Description:

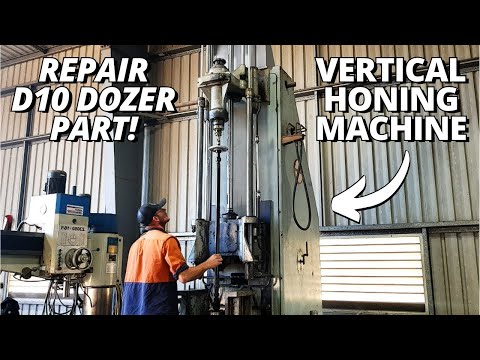

Explore the intricate process of repairing and replacing a Caterpillar D10 Dozer track adjuster cylinder in this detailed machining tutorial. Begin by setting up and machining the end of the old track adjuster cylinder on a TM-26120G lathe. Progress to machining the new barrel, turning down the outer diameter and boring the internal diameter of the hollow bar. Conclude with using a Delapena Vertical Honing machine to finish hone the internal diameter of the cylinder barrel to specification, preparing it for welding. Gain insights into various machining techniques, including the use of steady rests, live centers, and different cutting tools such as Palbit WNMG carbide inserts and shop-made boring bars. Observe the machining process at 145RPM spindle speed and learn about internal beveling and weld preparation. Finally, witness the use of a Sunnen ANR-S remote feed portable honing head to achieve precise internal dimensions.

Machining and Vertical Honing a Caterpillar Dozer Track Adjuster Cylinder

Add to list