Description:

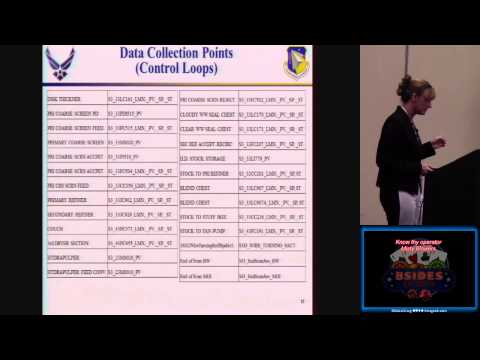

Explore a comprehensive analysis of industrial process monitoring and optimization in this BSidesLV 2014 conference talk. Delve into the complexities of data collection, control loops, and temporal alignment challenges in industrial settings. Learn about machine learning applications for tracing variability sources and behavior-based event detection systems. Discover innovative approaches to feature selection, cluster tuning, and threshold optimization. Gain insights into operator response characterization and state of health assessment techniques. Understand how these advanced methodologies can enhance industrial facility operations and security.

Know Thy Operator: Behavior-Based Event Detection in Industrial Facilities

Add to list

#Data Science

#Data Analysis

#Computer Science

#Machine Learning

#Engineering

#Electrical Engineering

#Control Systems

#Feature Selection

#Data Mining

#Cluster Analysis