Description:

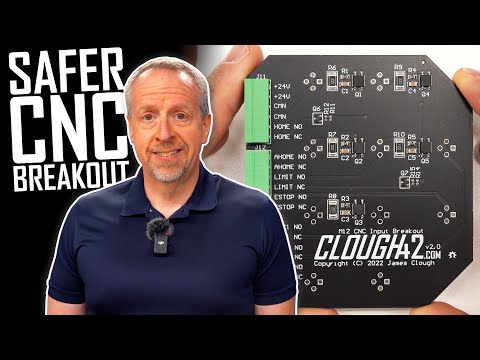

Explore the process of designing and building a safer M12 breakout board for an Avid CNC router with Centroid Acorn and Clearpath Servos in this detailed video tutorial. Learn about the differences between normally-open and normally-closed inductive proximity sensors, and discover how to implement combining logic to retain auto-squaring functionality. Follow along as the presenter walks through the schematic and PCB design, assembly process, and rigorous testing procedures. Witness problem-solving in action as issues are identified, addressed, and resolved through multiple iterations. Gain insights into SMT sample books, board modifications, and the development of improved solutions. By the end, acquire valuable knowledge about CNC controller breakout board design, electronic troubleshooting, and the iterative nature of engineering projects.

Making a Safer M12 Breakout Board

Add to list

#Engineering

#Manufacturing

#CNC

#Electrical Engineering

#Microcontrollers

#Circuit Design

#Electronics

#Soldering