Description:

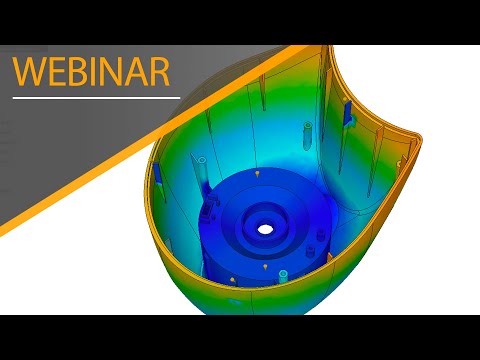

Explore injection molding simulation techniques to enhance plastic part moldability using Autodesk Fusion 360. Learn how to minimize mold tool rework, reduce part defects, and secure backup material options through a comprehensive demonstration of the Fusion 360 Simulation Extension. Discover how to simulate mold filling processes, utilize guided results with Design Advice, and leverage a database of over 10,000 material grades. Gain insights into identifying common issues such as sink marks, air entrapments, warpage, shrinkage, and weld lines. Follow along as the webinar covers topics including simulation environment setup, material selection, injection location placement, and result analysis. Dive into advanced features like multiple injection locations, guided results interpretation, and comparative views for optimizing plastic part designs. Enhance your understanding of injection molding processes and improve the manufacturability of your designs with this informative session.

Improve Plastic Part Moldability with Injection Molding Simulation - Autodesk Fusion 360

Add to list

0:00 / 0:00